Detailed Construction Instructions for Eps Heat Insulation Panels for Buildings

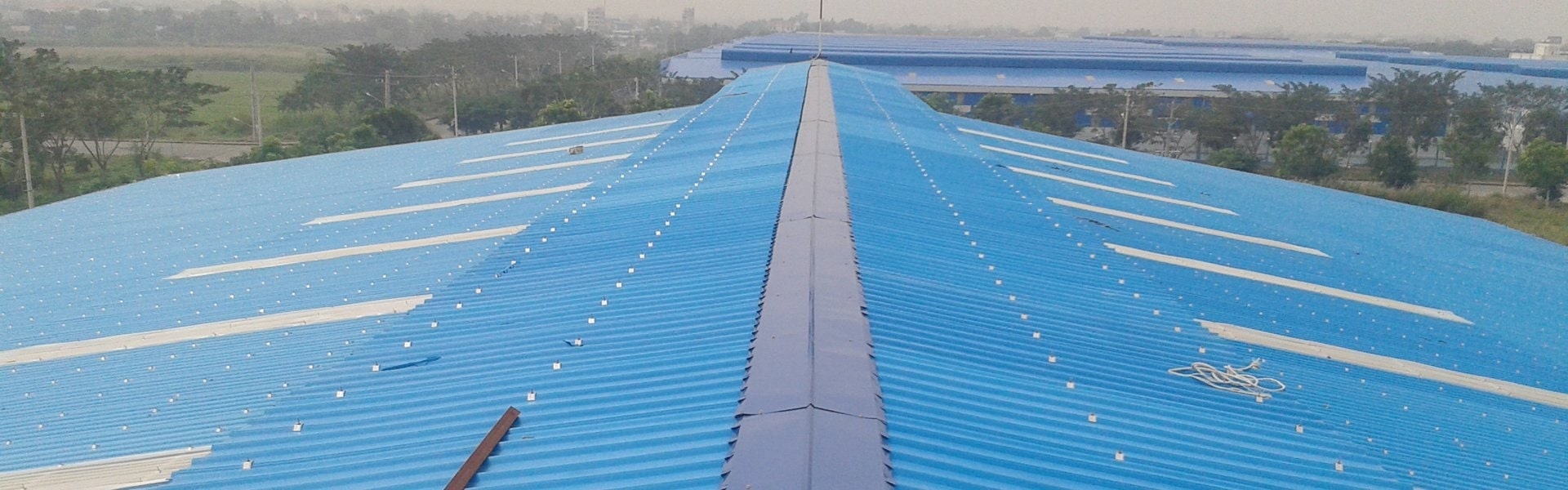

Insulated Eps Panel is one of the construction materials that are quite commonly applied in buildings with weak foundations, or projects that need quick construction, or require harsh assembly and construction conditions. In this article, Hai Lam will guide customers in detail how to construct insulation Eps Panel.

What is Eps Panel? Pros and cons of Eps panels in construction

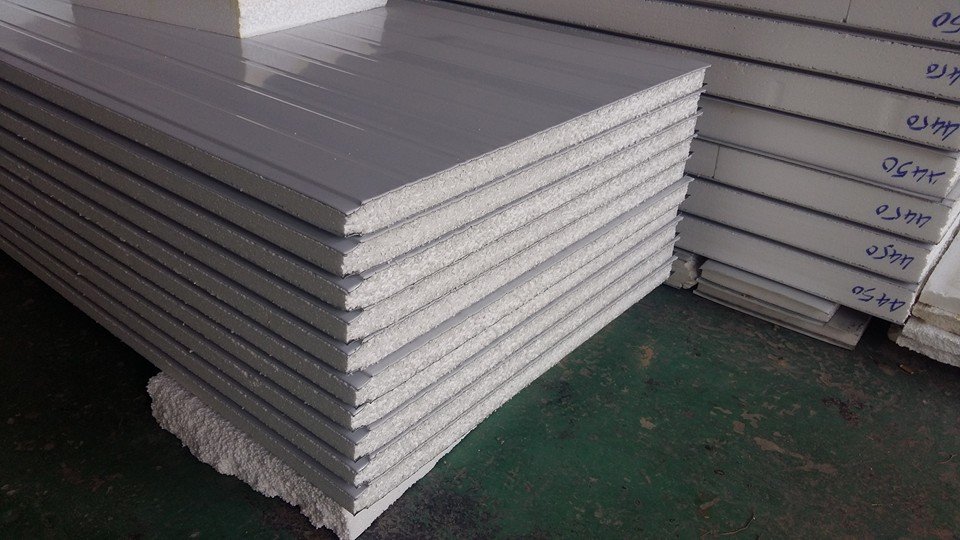

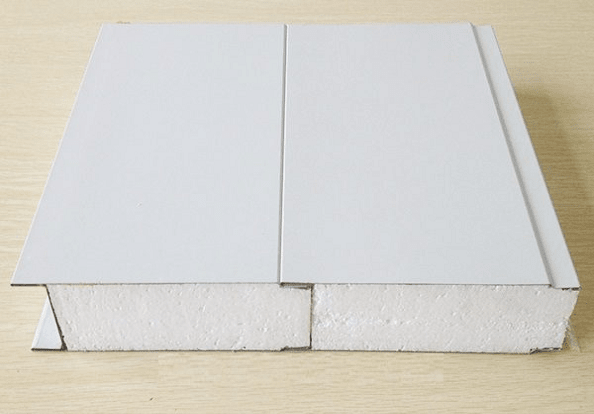

Eps panels are lightweight construction materials, used to construct prefab houses quickly. Therefore, Eps insulation panel has a simple structure of 3 layers in order: electrostatic corrugated iron - Eps layer - electrostatic corrugated iron. The advantages and drawbacks of insulated Eps Panel are:

|

Advantage |

Shortcoming |

|

|

How Many Common Types of Eps Panels Are There?

Eps Panel also has a variety of product lines to serve all your needs. Here are 3 types of Eps Panel that are popular with a large number of people:

1. 3-layer Eps insulation panel

This is the most popular product in all Tonmat lines, meeting international standards ISO 9001 - 2008. 3-layer eps panels help the rigidity of the building to be significantly enhanced, as well as increase sound and heat insulation for buildings and workshops. Product colors are also quite diverse and pleasing to the eye: light yellow, gray, milky white,...

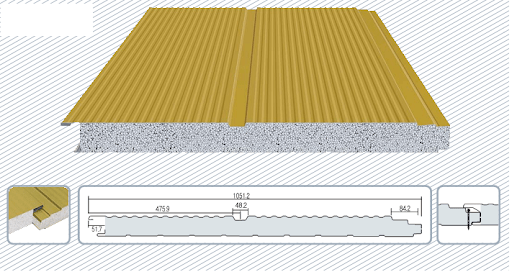

2. Ribbed insulated Eps panel

The structure is similar to 3-layer Eps panels, but this type has a grooved ribbed surface, which helps to drain well and keep the surface clean is also better. Because of this feature, they are often applied in projects such as laboratories, clinics ,... In addition, thanks to the corrugated ribbed structure, this Eps Panel has good rigidity, very stable.

3. Flat Panel Eps

This product is extremely fireproof. Therefore, they are often used to fight fires in buildings and factories,... However, the ability to resist oxidation and moisture resistance is slightly inferior to the product lines mentioned above, so use it for buildings with low humidity. In addition, because of the smooth surface, this product also helps to add aesthetics to the building.

How to Close Eps Insulation Panel for Sustainable, Effective Building

To close Eps panels to ensure the longevity and sustainability of products and buildings, please follow the following steps immediately.

- Step 1: Carry out survey, study the site, refer to drawings and appropriate construction plans

- Step 2: Prepare suitable construction tools and materials, ensure quality. Including: drills, ladders, shooters, labor protection tools,...

- Step 3: Mark the places to note to avoid confusion and errors with chalk, brushes,...

- Step 4: Start construction by bolting, installing Eps Panel. It is necessary to use crossbars, vertical bars. the U bar is intended to ensure the robustness of the ribs. Take care to carefully reinforce weak positions with an iron skeleton system

- Step 5: In hanging positions, reinforce with specialized tools

- Step 6: Start fitting the Eps panels into the completed frame. At places such as corners, corners,... It is necessary to use enclosure bars or corner bars to make the building more solid

- Step 7: Completion and acceptance of the Eps Panel installation project and put into use

Notes when constructing Eps Panel wall

In addition to properly closing the Eps Panel, during construction, you also need to pay attention to some details to ensure the best product experience.

- Choose Eps panels with an appearance that matches the general aesthetics of the project. Factors to consider are: color, texture (flat or ribbed), thickness,...

- When constructing, it is necessary to arrange the Eps panels meticulously and in line to create a sustainable structure for the project

- Use the right type of accessories of Eps Panel so that the joints are matched, thereby optimizing thermal insulation

- Calculate, carefully consider the heat expansion ability of Eps Panel panels

- Construction strictly according to the instructions

Hopefully, with the information provided by Hai Lam, customers will construct and install Eps Panel smoothly and accurately so that the project can be used for a long time!

Contact Information:

- Address: 07 Nguyen Khuyen Street - Hoa Khanh Nam Ward - Lien Chieu District - Da Nang City

- Email: info@hailam.com.vn

- Hotline: 0905.999.900

- Website: https://hailam.com.vn

- Funpage: hattapus://www.facebook.com/kongtitanhahillam

- What is MT roofing? How many waves should I use tonmat MT? - 17/06/2022

- What is fake roofing tiles? Note when buying! - 17/06/2022

- Tole Cliplock - Instructions for Transportation, Construction and Storage from Hai Lam - 08/12/2021

- What is Cliplock corrugated iron? Explaining the Popularity of Cliplock Corrugated Iron in the Central Region - 08/12/2021

- Is Tole Klip Lok Really Good For Construction? Review From Hai Lam - 08/12/2021

- All Basic Information About Tonmat Hai Lam Company - 28/10/2021

- Price List of Seamlock Corrugated Iron and Seamlock Corrugated Iron Accessories, Original Factory Price | Hai Lam - 27/10/2021

- Beautiful plastic curtains, price list for installing heat-insulated curtains 2021 | Hai Lam - 24/10/2021

- Address to Buy Da Nang Plastic Lattes at Good Prices for All Projects - 24/10/2021

- 100+ Mẫu La Phông Trần Nhà Đẹp Tô Điểm Công Trình 2021 - 24/10/2021