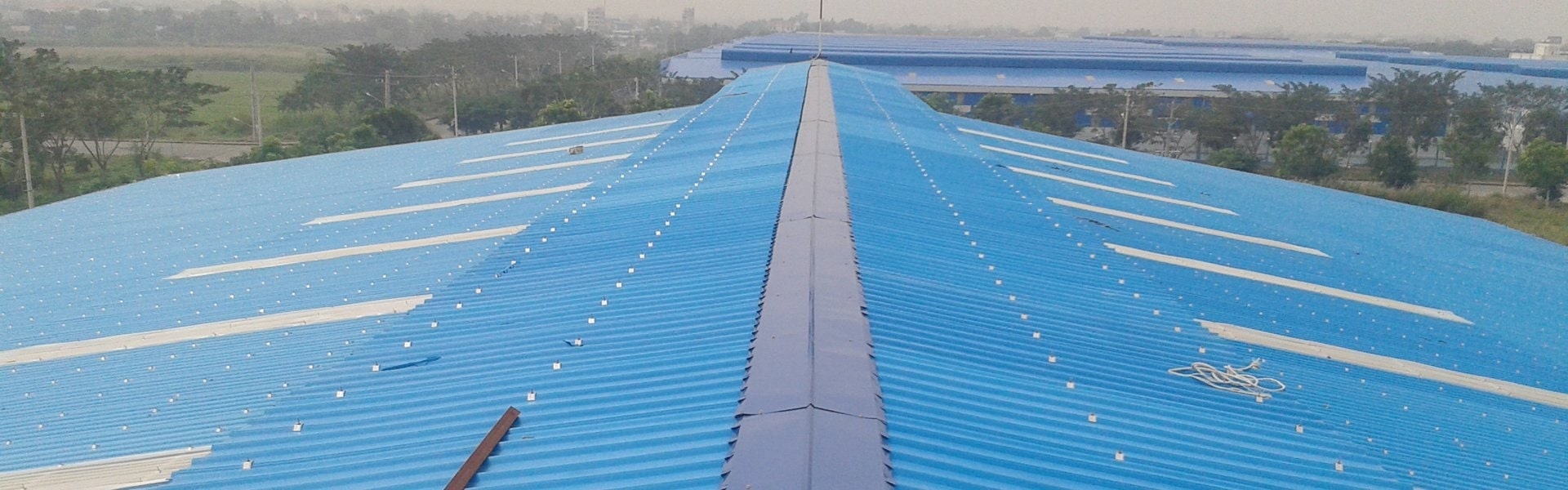

In order to serve projects requiring large roof areas, Seam lock corrugated iron was born with outstanding properties: heatproof, waterproof, windproof, anti-corrosion,...

Overview:

Seam lock corrugated iron was born to compensate for the weaknesses of traditional roof corrugated iron. Thanks to that, projects using Seam lock corrugated iron will resist heat well, withstand high winds, and minimize the risk of corroded corrugated iron and water leakage. Seam lock corrugated iron is suitable for projects that require a large corrugated iron roof area such as factories, warehouses, gymnasiums,...

.

1. Materials of Seam lock corrugated iron

Galvanized steel is the core material that makes up a Seam lock corrugated iron sheet. In addition, the different properties of the anti-corrosion layer along with the color plating layer will make Seam lock corrugated iron more diverse and rich. The following is Seam lock corrugated iron with different materials:

Zinc sheets: Seam lock zinc sheets have galvanizing technology in accordance with Japanese JIS standards

- Colored zinc sheets: Seam lock colored zinc sheets are galvanized on both sides of the sheet, with many colors for customers to choose from to suit the aesthetics of the project.

- Cold sheet: Seam lock cold sheet, because it is plated with a layer of zinc-aluminum alloy, has superior properties compared to Seam lock zinc sheet, for example: better heat resistance, better oxidation resistance,...

- Colored cold steel: Seam lock color cold steel is similar to cold steel but is more special in that it is coated with an additional layer of arbitrary color to suit the customer's project design needs.

2. Thickness of Seam lock corrugated iron

Seam lock corrugated iron has a minimum thickness of 0.35 mm and can be up to more than 2.50 mm thick. Customers can choose a Seam lock corrugated iron sheet with a thickness within the above range to suit the construction project.

3. Length of Seam lock corrugated iron

Customers can request the length of Seam lock corrugated iron as much as they want because Seam lock corrugated iron is not limited in length or usable area. Therefore, customers can safely choose Seam lock roofing sheets for all large and small projects.

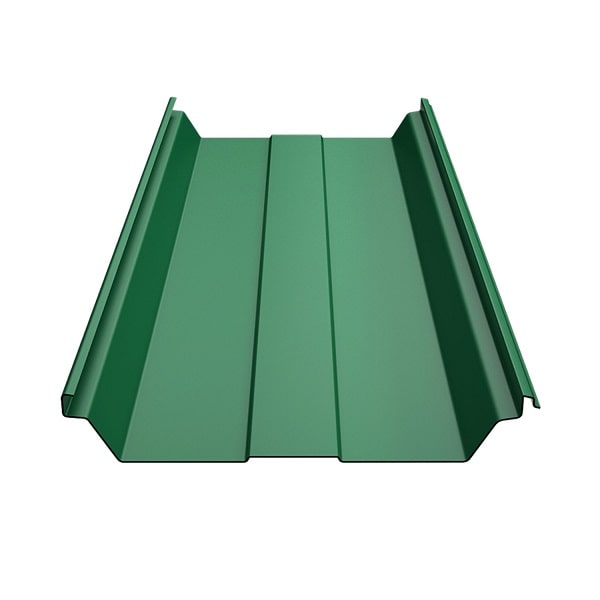

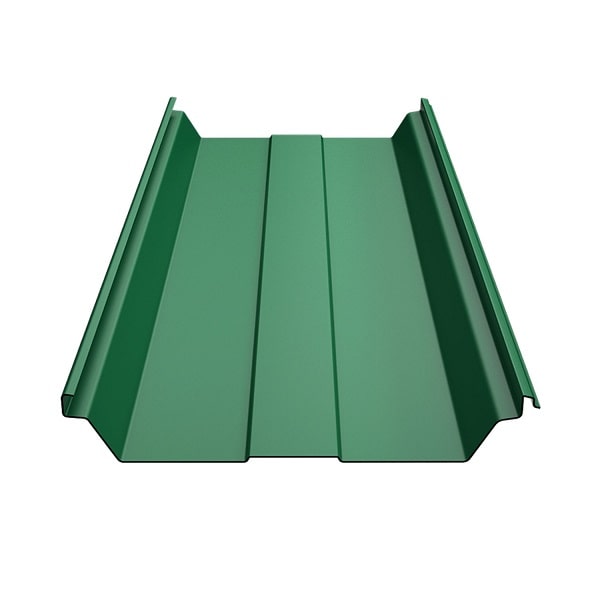

4. Color of Seam lock corrugated iron

Seam lock corrugated iron has a variety of colors because colored cold corrugated iron and colored zinc corrugated iron are coated with a layer of color paint. Customers can choose the color of this color coating for Seam lock corrugated iron. Because the colors are diverse and rich and can be freely chosen, they are very popular with those who love beauty and want their projects to have unique features.

>> See more: Seamlock Corrugated Steel Price Quote for Construction Projects in the Central Region

5. What accessories does Seam lock need?

In order for Seam lock corrugated iron to fully promote its effectiveness and at the same time enhance its beauty, we often use accessories that come with Seam lock corrugated iron such as: belt screws, Seam lock corrugated iron clamps, corrugated iron corrugated iron clamps. Seam lock, gutter accessories, fringe accessories, peak stop accessories, tail stop accessories,...

6. Advantages and disadvantages of Seam lock corrugated iron

Seamlock corrugated iron has very special advantages compared to other common types of corrugated iron. Besides, it also carries some significant disadvantages. Clearly understanding the advantages and disadvantages of seamlock roofs will help you consider and choose the right roof for your project.

|

Advantage |

Defect |

|

|

>>> See more: Seamlock corrugated iron, Roofing for all large area projects

>>> See more:

- Seam Lock corrugated iron technology

- Technical specifications of Seam Lock corrugated iron

- Other information

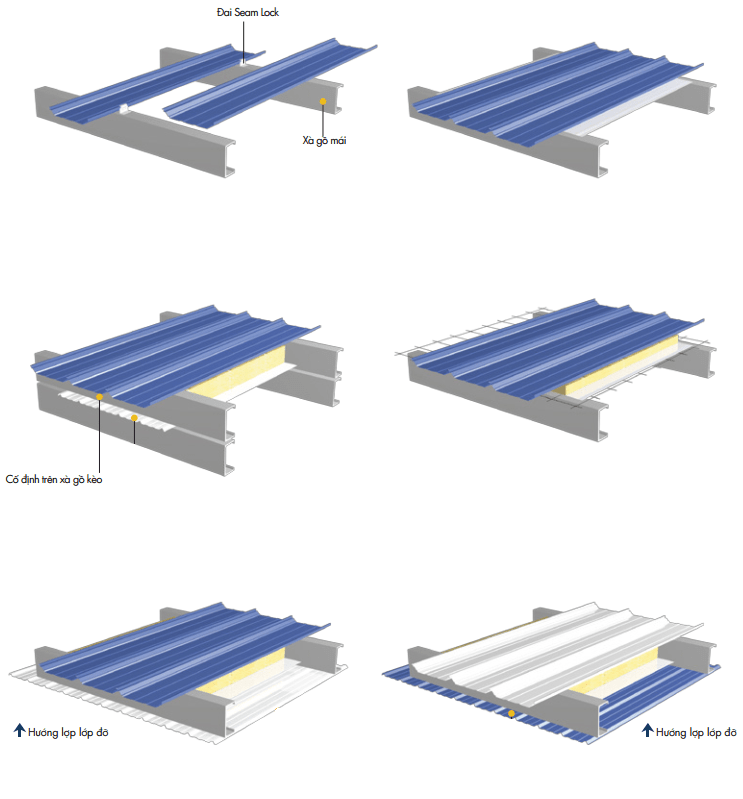

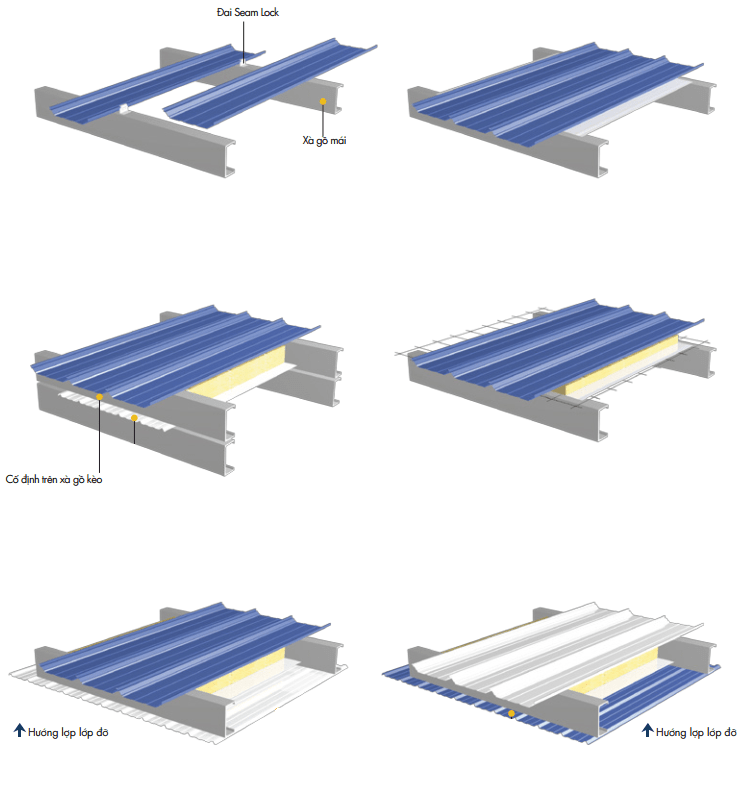

Technology:

Seam lock corrugated iron is manufactured and processed according to technology from leading international countries such as Japan, Europe,... so the product ensures high quality and construction safety. Below is the Seam lock roofing technology commonly used for projects:

>>> Reference:

- Cliplock Corrugated Iron Information and Reputable Suppliers in the Central Region

- Cliplock Corrugated Iron Price Quote 2021 For Construction Projects In The Central Region

- Overview of Seam Lock corrugated iron

- Technical specifications of Seam Lock corrugated iron

- Other information

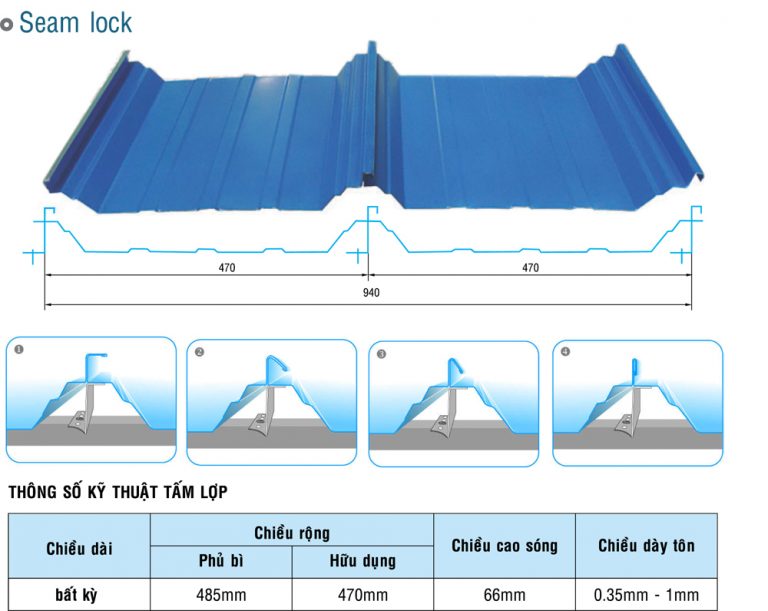

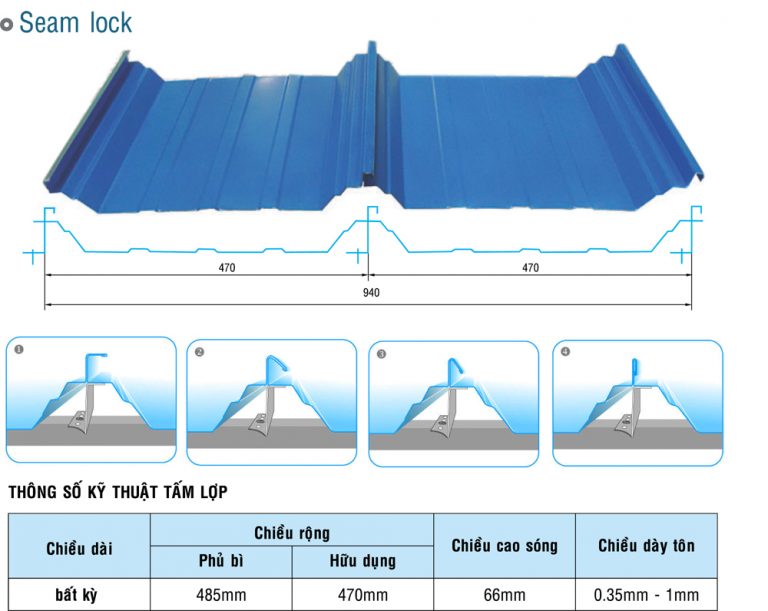

Specifications:

There are 3 lines of seam lock corrugated iron commonly used on the market today, which are: seam lock corrugated iron 485, seam lock corrugated iron 470 and seam lock corrugated iron 1040. The following is a detailed table of technical specifications of the three lines of embossed seam lock corrugated iron. language:

|

No |

EMBRYOLOGY |

LENGTH |

WIDTH |

WAVE HEIGHT |

THICKNESS OF SHEETS |

|

|

PHU BI |

EFFECTIVENESS |

|||||

|

1 |

597 ÷ 600 mm |

Bất kỳ |

500 mm |

485 mm |

60 mm |

0.35 ÷ 0.70 mm |

|

2 |

/ |

Bất kỳ |

485 mm |

470 mm |

66 mm |

0.35 ÷ 1 mm |

|

3 |

/ |

Bất kỳ |

1200 mm |

1040 mm |

70 mm |

1.35 ÷ 2.53 mm |

>>> See more:

Other information:

To maximize durability and promote the effectiveness of Seam lock corrugated iron, please follow the following notes when using:

When you want to move the finished corrugated iron, tie it tightly

To avoid dents and scratches on Seam lock sheets, be very careful when removing, installing, and dismantling

Limit the friction of finished products on rough and rough road surfaces

Do not let hard objects drag on the Seam lock surface

>>> See more:

- Overview of Seam Lock corrugated iron

- Seam Lock corrugated iron technology

- Technical specifications of Seam Lock corrugated iron

RELATED PRODUCTS

- Mail: info@hailam.com.vn

- Skype : hailam.com.vn

- Hotline : 0905999900