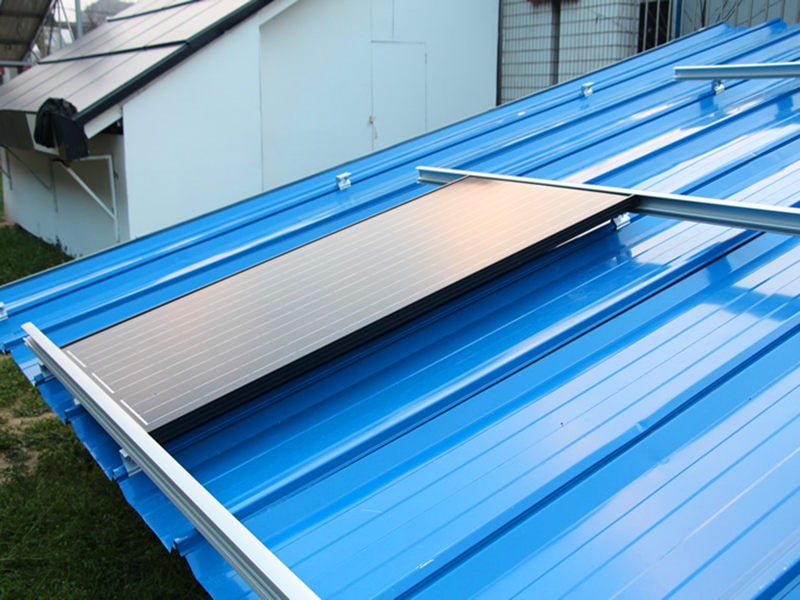

Clip lock corrugated iron has accessories included when assembling such as cliplock corrugated iron clamps, etc. Hai Lam specializes in providing construction materials nationwide, including transporting cliplock corrugated iron sheets in Hanoi or Da Nang.

Overview:

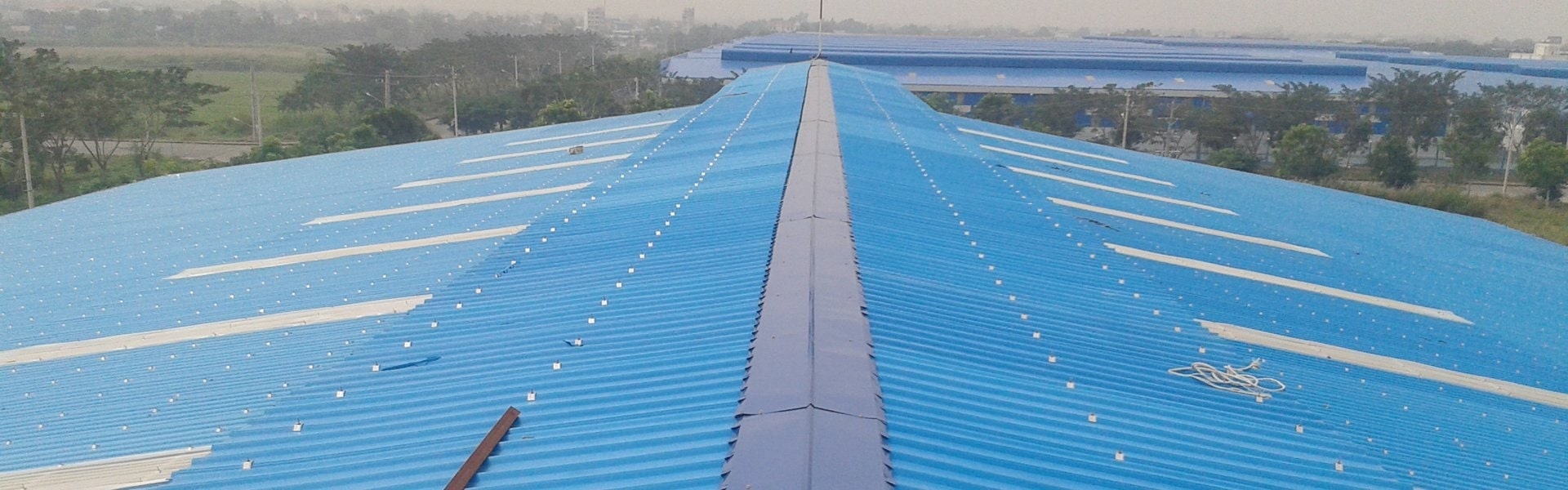

Clip lock corrugated iron is produced from the most advanced and modern technological line today and is made from materials such as cold-rolled corrugated iron, zinc corrugated iron, etc. It was created to meet the needs of projects requiring the ability to The ability to quickly drain water on corrugated iron roofs, large and long roofing areas, for example: factories, parking lots, train platforms, etc., so cliplock roofing has advantages in durability, waterproofing, and drainage. water and is almost not affected by the environment (because corrugated iron is not used directly to close the roof)..

1. Materials of Clip lock corrugated iron

Clip lock roofing sheets are made from super durable material, Colorbond steel. Besides, on the market there are also cliplock sheets made from steel plated with aluminum-zinc alloy. Therefore, clip lock corrugated iron is completely sturdy with a thickness of 42 bmt or 48 bmt klip lok and has extremely perfect durability.

2. Thickness of Clip lock corrugated iron

The thickness of clip lock panels ranges from 0.35 mm to 0.60 mm. With corrugated iron sheets of different thicknesses, customers can freely choose for themselves the most satisfactory thickness, suitable to the construction needs and aesthetics of the project.

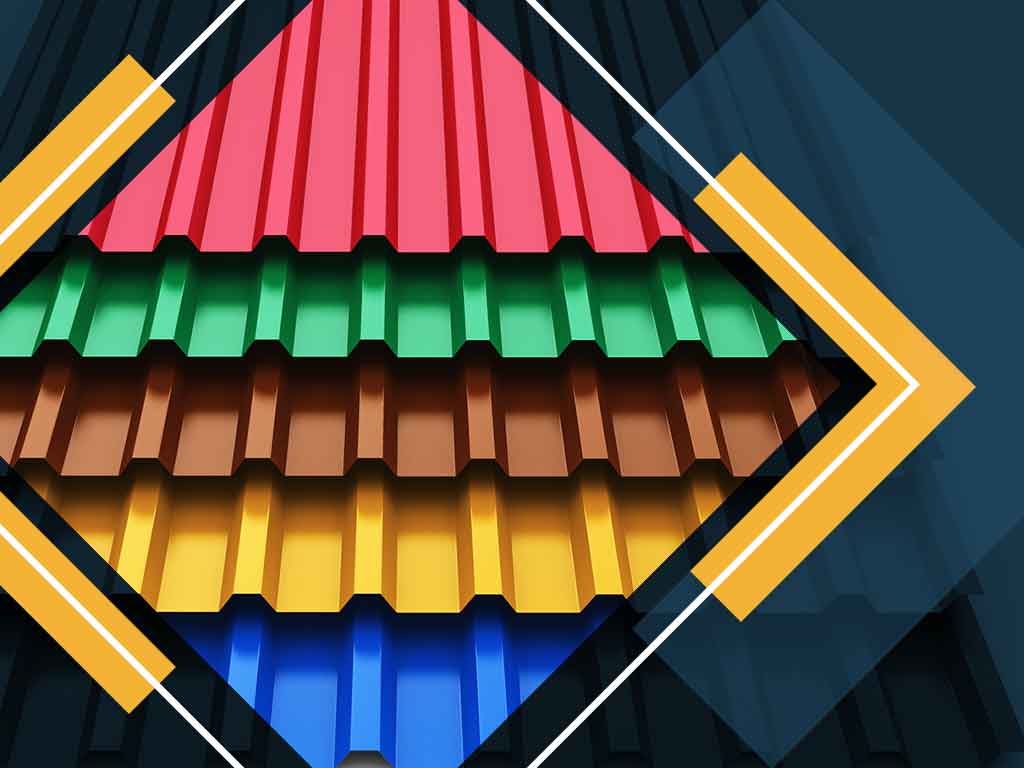

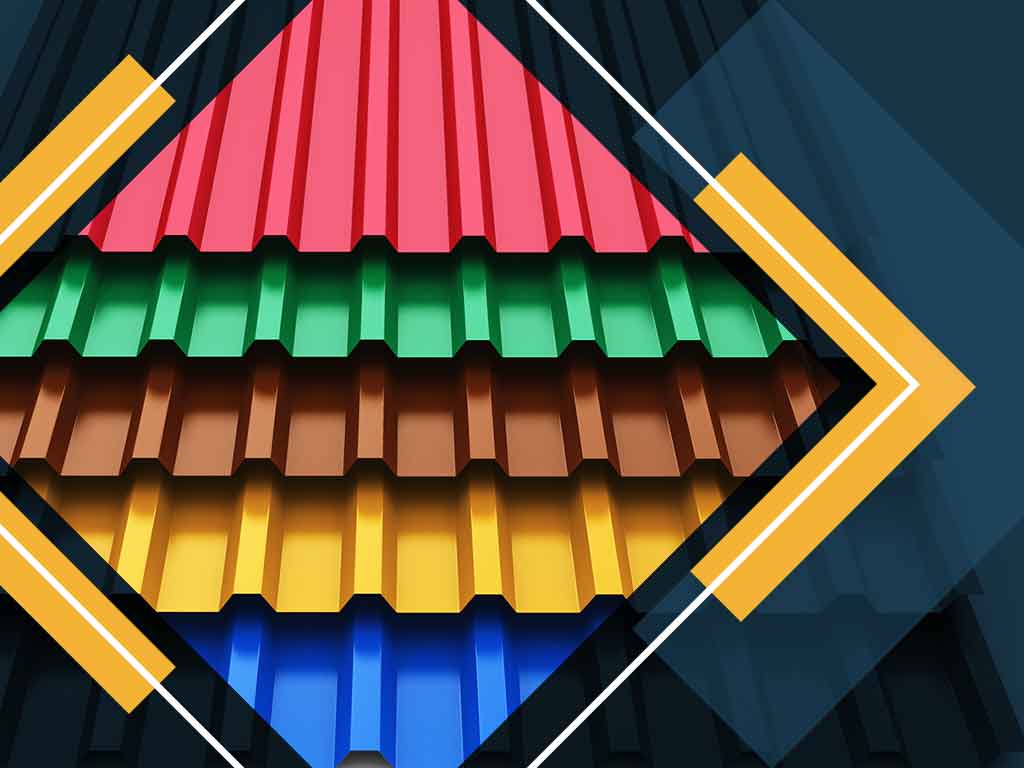

3. Color of Clip lock corrugated iron

Clip lock corrugated iron has a variety of colors that are not inferior to seam lock corrugated iron. The color of clip lock corrugated iron is expressed from neutral tones, warm tones, cold tones with many different shades, nothing is missing. Because of such many choices, customers can rest assured that their construction is always eye-catching, beautiful and aesthetically consistent with the original design.

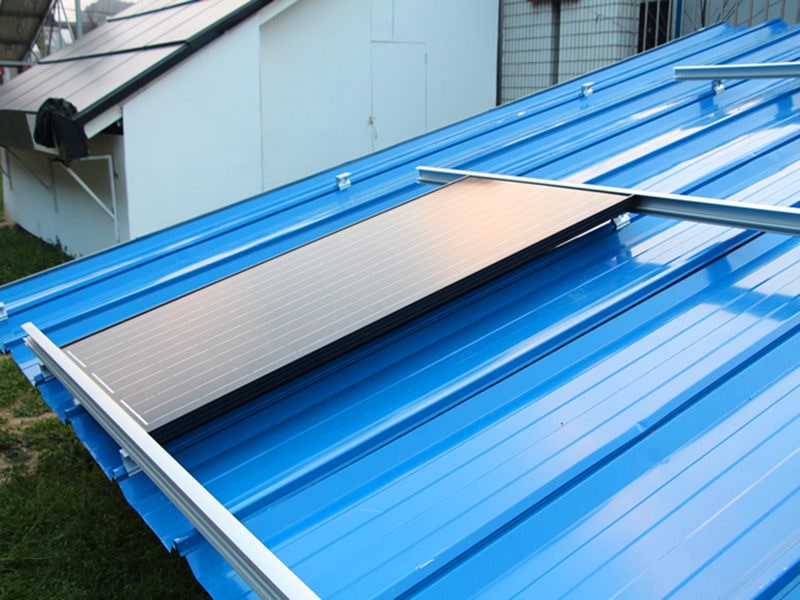

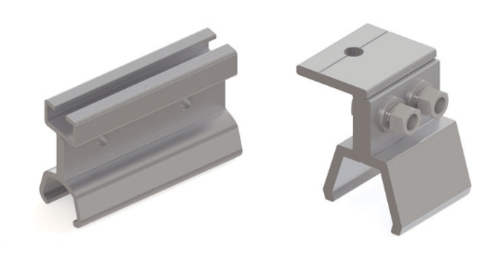

4. Clip lock accessories included

When purchasing clip lock corrugated iron, those directly performing the construction often purchase the following accessories:

Clip lock corrugated iron belt

Gutter

Lam wind (also known as louver)

Belt firing screw

Roof down

Types of frills

Water collection hopper

Foam cliplock

Other types of materials belong to the mechanical industry

>>> See more:

- Cliplock corrugated technology

- Technical specifications of cliplock corrugated iron

- More information about cliplock corrugated iron

Technology:

To create cold clip lock corrugated iron, the production line must meet the following standards:

JIS 3321 Japanese Industry

A792/A792M USA ASTM

EN 10346 Europe

AS 1397 Australia

MS 1196 Malaysia

To get colored clip lock corrugated iron sheets, the factory must comply with the following standards:

JIS 3312, JIS 3322 Japanese Industry

A755/ A755M USA ASTM

AS 2728 Australia

>>> See more:

- Overview of cliplock corrugated iron

- Technical specifications of cliplock corrugated iron

- More information about cliplock corrugated iron

Specifications:

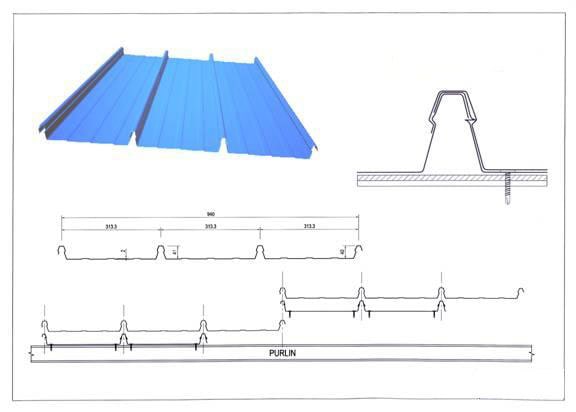

Clip lock corrugated iron includes 4 main product lines:

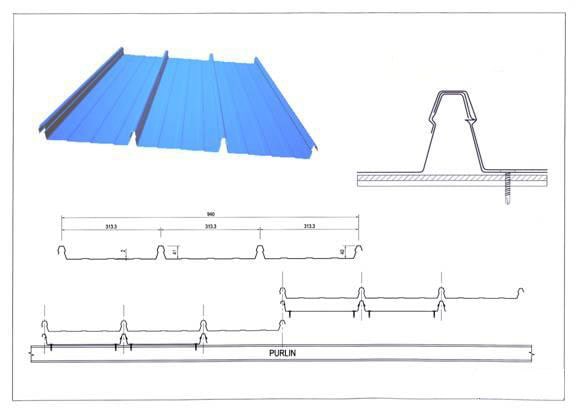

Corrugated clip lock 940 (4 waves)

Corrugated clip lock 945 (4 waves)

Corrugated clip lock 970 (4 waves)

Corrugated clip lock 406 (3 waves)

Specifications of cliplock corrugated iron generally comply with the indicators in the table below:

|

Criteria |

Specifications |

Unit |

|

Corrugated intensity |

G550 |

mpa |

|

Effective suffering |

400 (± 3) |

mm |

|

Wave height |

42 (± 2) |

mm |

|

Thickness of corrugated iron |

0.35; 0.40; 0.45; 0.50 |

mm |

|

Weight 450 mm |

|

kg/m2 |

|

PU layer thickness |

10; 25; 40; 50; 60 (± 2) |

mm |

|

PU density (kg/m3) |

38 ± 3 |

kg/m3 |

|

Thermal conductivity coefficient (W/m.K) |

0.028 |

TCVN 7194 - 2002 |

|

Dehumidification ratio |

0.38 |

|

|

Water absorption rate by mass |

0.74 |

|

|

Soundproofing ability |

27.5 |

>>> See more:

- Cliplock corrugated technology

- Overview of cliplock corrugated iron

- More information about cliplock corrugated iron

Other information:

Customers need to pay attention to the following recommendations when transporting and constructing clip lock corrugated iron to ensure safety and durability of the corrugated iron:

- To prevent the clip lock from being scratched or deformed, please be very careful during assembly and dismantling

- Remember to tie the finished corrugated iron tightly if the constructor wants to move it

- Absolutely do not let rough, hard objects rub strongly on the clip lock surface

- Minimize the dragging of finished corrugated iron onto rough road surfaces

>>> See more:

- Cliplock corrugated technology

- Overview of cliplock corrugated iron

- Technical specifications of cliplock corrugated iron

RELATED PRODUCTS

- Mail: info@hailam.com.vn

- Skype : hailam.com.vn

- Hotline : 0905999900